It can be extremely challenging for businesses to effectively manage complex supply chains while ensuring the timely delivery of products, minimizing costs and maintaining high quality. A solution to help with this challenge is the implementation of a Supply Chain Control Tower (SCCT).

A SCCT is a concept and technology platform used in supply chain management to provide end-to-end visibility, orchestration, and optimization of the entire supply chain network. It acts as a centralized hub where all relevant data and information related to the supply chain operations are collected, analyzed, and managed in real-time or near-real-time.

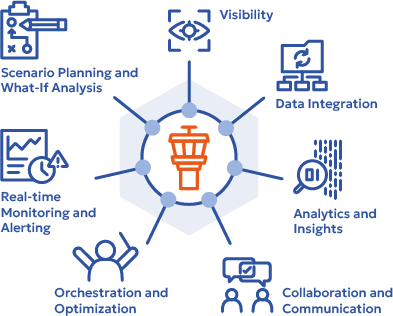

Key features and functions of a SCCT

To recognize the value of a SCCT, you need to better understand its key features and functions, which include the following:

Let’s take a closer look at each of them below.

Visibility

It provides comprehensive visibility into various aspects of the supply chain, including inventory levels, order status, shipment tracking, supplier performance, and demand forecasts. This visibility allows stakeholders to monitor operations and identify issues or disruptions promptly.

Data integration

A control tower integrates data from multiple sources and systems across the supply chain, such as ERP (Enterprise Resource Planning) systems, WMS (Warehouse Management Systems), TMS (Transportation Management Systems), IoT (Internet of Things) devices, and external data sources like weather forecasts and market trends.

Analytics and insights

By leveraging advanced analytics techniques such as predictive analytics, machine learning, and data visualization, control towers can generate actionable insights from the collected data. These insights help in identifying patterns, trends, and potential risks, enabling proactive decision-making and problem-solving.

Collaboration and communication

Control towers facilitate collaboration and communication among various stakeholders within the supply chain network, including suppliers, manufacturers, distributors, logistics providers, and customers. This collaborative approach fosters transparency, agility, and responsiveness across the entire ecosystem.

Orchestration and optimization

Control towers enable the orchestration and optimization of supply chain processes and activities by automating workflows, identifying bottlenecks, and recommending optimal actions. This helps in streamlining operations, reducing costs, and improving overall efficiency and performance.

Real-time monitoring and alerting

They provide real-time monitoring of key performance indicators (KPIs) and critical events within the supply chain. Automated alerts and notifications are generated to notify stakeholders about deviations from plans, delays, or other issues requiring immediate attention.

Scenario planning and what-if analysis

Control towers support scenario planning and what-if analysis to simulate various supply chain scenarios and assess their potential impact on operations, costs, and service levels. This capability enables better decision-making and risk management strategies.

Conclusion

Overall, a SCCT serves as a strategic tool for managing and optimizing complex supply chain networks in today’s dynamic and interconnected business environment. It helps organizations to enhance agility, resilience, and competitiveness while meeting customer expectations and adapting to changing market conditions.